Our brand-new »Heavy Duty«

compressed air sprayers

The trigger spray bottles in our Masterpiece Line offer the perfect solution, the first of its kind on the market. New, aggressive fluids corrode the materials they come into direct contact with. After just a few applications these liquids make conventional spraying bottles unserviceable. The compressed air sprayers in the new Kläger brand Masterpiece Line are reliable, professional products that guarantee continuous, safe spraying.

Award „winner“!

Masterpiece Line received German Innovation Award

The products in the Masterpiece Line are among the winners of the coveted German Innovation Award 2022. In the “Excellence in Business to Business – Materials & Surfaces” category, the professional sprayers in the Masterpiece Line received the accolade of “Winner”, both for their special chemical resistance to aggressive media and their outstanding level of innovation.

We are very proud that the jury honoured our great innovative achievement and long development work and awarded the Masterpiece Line product family with its appealing contemporary, black design as “Winner” in its category.

Top-level performance with solvents and alcohol mixtures, as well as concentrated acids and solvents and cleaning agents in their pure form

After many years of researching raw materials, product development, live testing and a personal exchange of ideas with real users and end customers, we have chosen special high-tech materials. Additionally we made significant advancements in the construction design of our active components. Over the next few years, the Masterpiece Line pressure sprayers will replace single-use aerosols and trigger sprayers. Even expensive, large and complex spraying systems made of metal. Therefore, they are the perfect addition to our product range.

MATERIALS

Chemical resistance & sustainability

The products in our Masterpiece Line are designed with maximum robustness for use with many special liquids. This means these professional pressure sprayers can be used significantly longer and need to be replaced far less often. There is now an alternative to the inconvenience of spray cans.

Considerably less aluminium and plastic waste is produced: an advantage, since such containers are usually difficult to dispose of and cannot be recycled with normal waste due to their contents.

Safety is our top priority

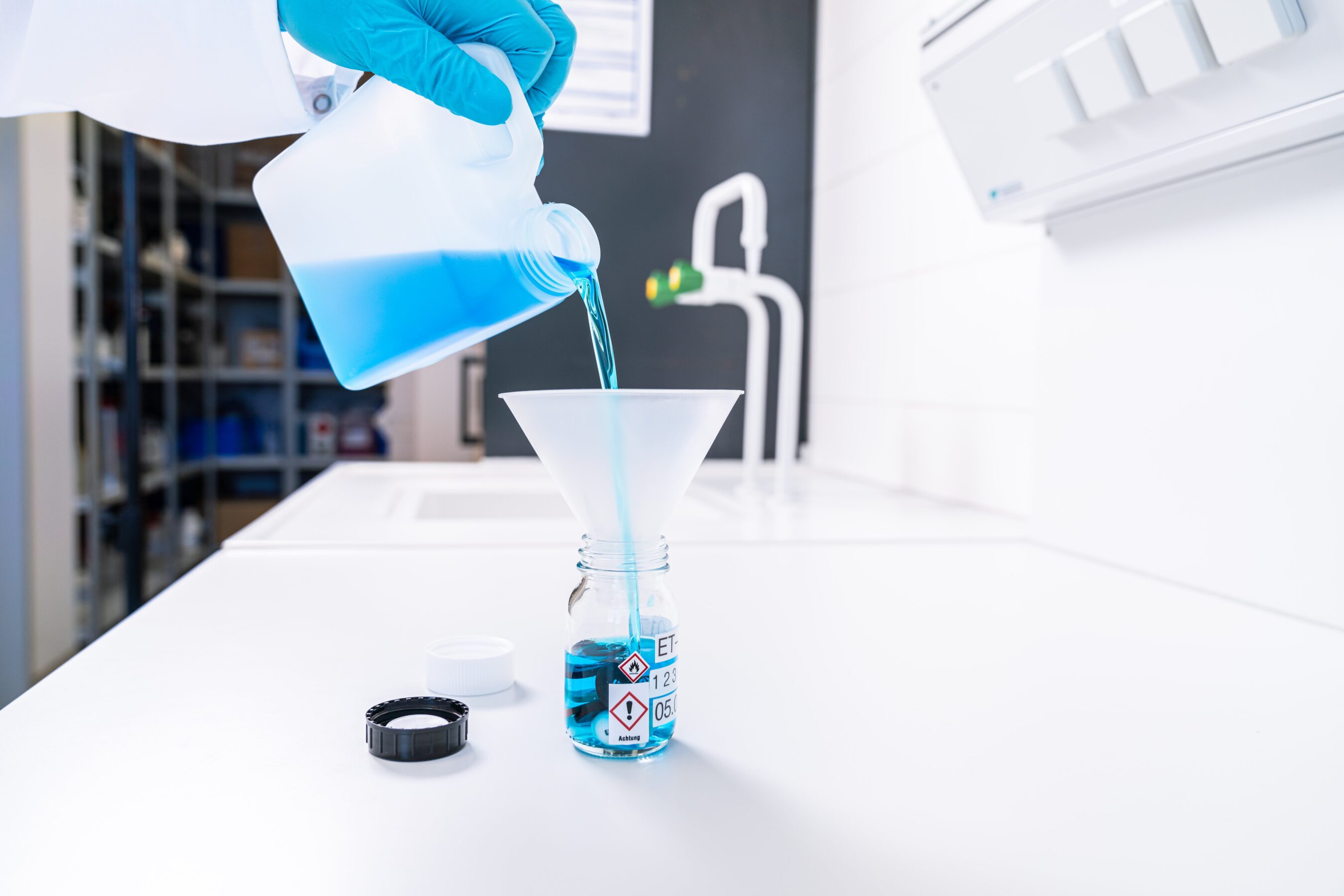

More and more innovative, highly effective chemicals are being sold in canisters, containers and drums. Before its actual use for an industrial, trade or commercial application, the liquid has to be decanted into an easy-to-handle yet extremely robust compressed air sprayer, in order to guarantee accurate application and spraying.

When using aggressive chemicals in containers with an operating pressure of 3 to 4 bar, safety is always our top priority.

Master Solve+

Our pressure sprayer for crude oil-based solvents and aggressive mixtures.

Solve+: Resistant to the following chemical compounds

- high-percentage solvent mixtures made of acetates, ketones (high concentration of acetone), xylene, toluene, different alcohols and other partly aggressive chemical substances

- the most widely used acetates, butyl acetate and ethyl acetate in higher concentrations than were previously possible

- higher concentrations of glycol ether and cyclohexane

- special mixtures containing naphtha (crude oil-based), minderal oil and petroleum-based solvents

Product examples

- brake cleaners with acetate (high concentration)

- safety cleaners and cold cleaners

- engine, machine and parts cleaners

- fast-acting degreasers

- silicon, paint and adhesive removers

- nitro and wash thinners

- corrosion protection and rust converters

- many other product groups in the solvent sector

Product specifications

- meets the maximum safety standards – long nozzle head for additional space between the user and the spray mist

- ErgoGrip sits comfortably in the hand, for a secure hold during use

- Continuous spray button for greater comfort during long spray jobs

- robust container + recessed grip with above-average stability and visibility stripes to display the level of liquid

- automatic safety valve, located securely protected inside the container, which locks the pump function when the maximum pressure goes above 3 to 4 bar

- infinitely adjustable nozzle for a defined jet or mist covering a larger area

- option of adding a custom label

- extensive product world of features and accessories

Acid+: Resistant to the following chemical compounds

- many inorganic special acids such as mixtures with a composition of up to 30% hydrochloric acid

- mixtures containing up to 5% hydrofluoric acid (fluorhydric acid) (threshold value chosen for safety reasons)

- mixtures containing certain proportions of hydrochloric acid, hydrofluoric acid and phosphoric acid

- acid-based media, alcohols (isopropanol, ethanol), heavily diluted alkaline liquids (up to pH 9.5)

Product examples

- wheel rim cleaners (acid-based)

- descaling agents

- sanitary cleaners and toilet cleaners

- swimming pool and pool cleaners

- rust bloom remover

- cement cleaners

- stone and paving stone cleaners

Product specifications

- meets the maximum safety standards – long nozzle head for additional space between the user and the spray mist

- ErgoGrip sits comfortably in the hand, for a secure hold during use

- Safety button that locks automatically: the contents cannot be sprayed accidentally

- robust container + recessed grip with above-average stability and visibility stripes to display the level of liquid

- automatic safety valve, located securely protected inside the container, which locks the pump function when the maximum pressure goes above 3 to 4 bar

- infinitely adjustable nozzle for a defined jet or mist covering a larger area

- option of adding a custom label

- extensive product world of features and accessories

Master Clean+

Our pressure sprayer with maximum resistance to solvents and cleaning agents in their pure form.

Clean+: Resistant to the following chemical compounds

- pure acetone (very frequently used in its pure form as a solvent and cleaning agent)

- pure methyl ethyl ketone (also known as MEK or 2-butanone)

- pure alcohol: ethanol, isopropyl alcohol (= 2-propanol) or methanol

Product examples

- acetone cleaner (e.g. for stripping varnish and paint, for removing resins, for degreasing and removing oil, etc)

- solvents or cleaning agents consisting of pure MEK

- ethanol, isopropyl alcohol or methanol

Product specifications

- meets the maximum safety standards – long nozzle head for additional space between the user and the spray mist

- ErgoGrip sits comfortably in the hand, for a secure hold during use

- Continuous spray button for greater comfort during long spray jobs

- robust container + recessed grip with above-average stability and visibility stripes to display the level of liquid

- automatic safety valve, located securely protected inside the container, which locks the pump function when the maximum pressure goes above 3 to 4 bar

- infinitely adjustable nozzle for a defined jet or mist covering a larger area

- option of adding a custom label

- extensive product world of features and accessories

CHEMICAL APPLICATION CENTER

Perhaps you want to apply an existing chemical, or one you have developed yourself, effectively, efficiently and safely?

Our experienced applications engineers, spray technology experts and Doctors of Chemistry in our in-house Chemical Application Center and the Regulatory Affairs department will advise you and guide you towards the right product. We will test your individual liquid, determine the correct resistance variant and recommend special upgrade and tuning options, e.g. with regard to spray pattern and precise application.

Masterpiece Line

Masterpiece Line Pressure Sprayers

Pressure Sprayers Trigger Sprayers

Trigger Sprayers Bottles & Caps

Bottles & Caps Precision components made of high-performance plastics

Precision components made of high-performance plastics Innovative hybrid parts

Innovative hybrid parts