The process is the product

Our team of specialists works in compliance with the ISO 9001, ISO 14001 and IATF 16949 management systems and accompanies our customers throughout the whole product life cycle, from the initial idea and request for quote to the planning of follow-on tools and capacity tools in large-scale injection-moulding production. In collaboration with our internal development and design department, as well as with our in-house toolroom, we work closely with our customers throughout the requisition and innovation process.

The starting point and, indeed, core of the Kläger philosophy is that our key account management works hand in hand with the customer’s own experts and decision-makers, right from the initial ideas and development, as part of the overall product project planning. This is the fast, efficient way to ensure added value for both parties.

Material expertise: high-performance plastic

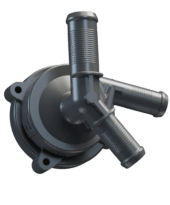

High-performance plastics such as PPS score high with their outstanding resilience. What’s more, we know this material category at the top of the plastic pyramid like the back of our hand. In comparison to traditional technical plastics, PPS is more reliable and can withstand significant differences in temperature, extreme pressure and the long-term effects of aggressive chemicals, such as fuel.

Over the past decades, we have proved our expertise when it comes to producing the most complex PPS parts at the very limits of possibility, even in large series, achieving the closest tolerances and highest process capabilities. We are proud of the fact that there are millions of vehicles throughout the world equipped with precision components and product systems made of Kläger brand high-performance plastics.

How can we help you?

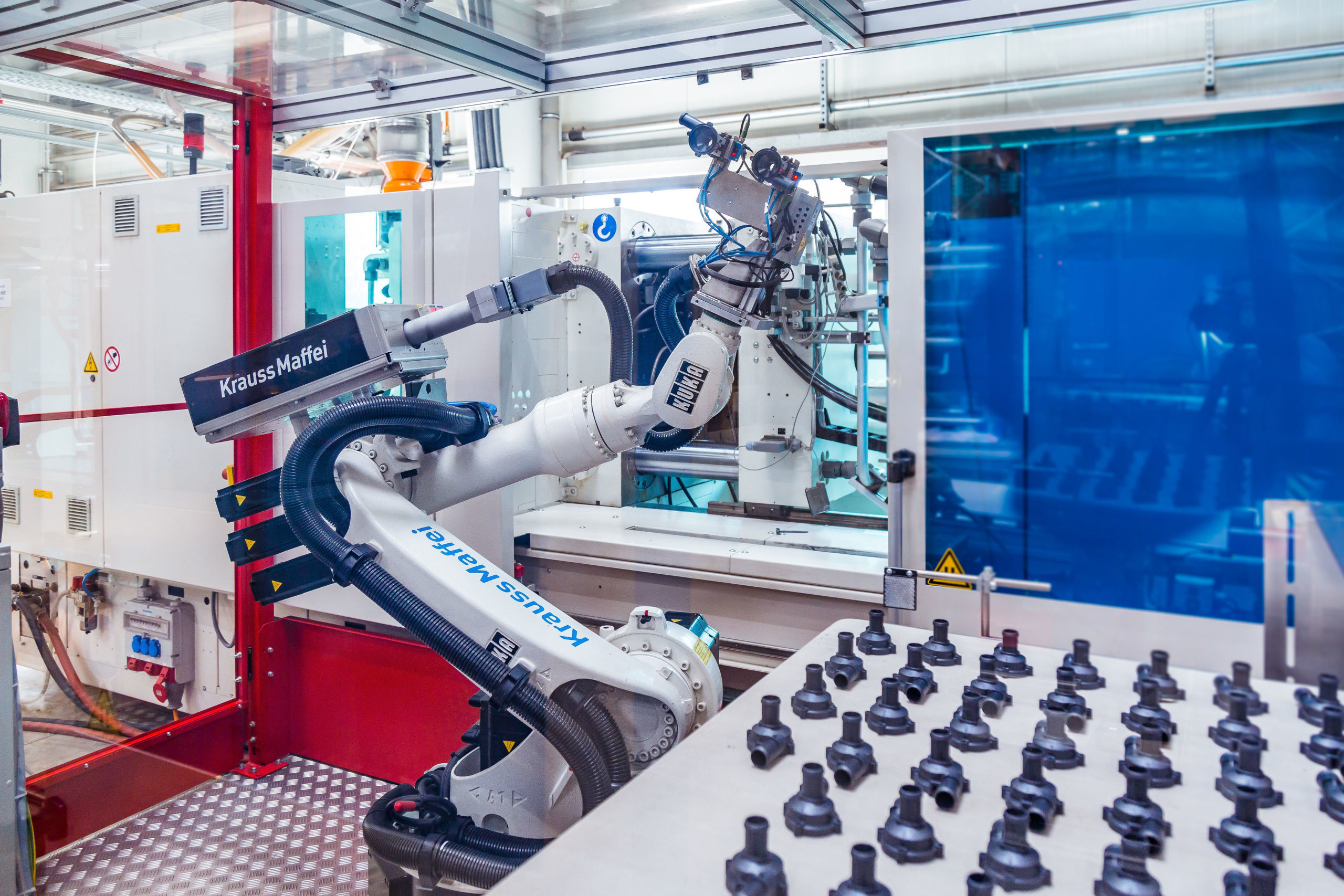

Our team of specialists uses more than 70 injection moulding machines made by renowned manufacturers such as KRAUSSMAFFEI, DEMAG, ENGEL and ARBURG to produce sophisticated technical precision components and product systems made of high-performance plastics with a high level of dimensional accuracy and surface consistency.

Find out more about our expert services!

Masterpiece Line

Masterpiece Line Pressure Sprayers

Pressure Sprayers Trigger Sprayers

Trigger Sprayers Bottles & Caps

Bottles & Caps Precision components made of high-performance plastics

Precision components made of high-performance plastics Innovative hybrid parts

Innovative hybrid parts